-

Gat No 611 , Mouje-Kuruli, MIDC Chakan, Tal-khed Pune - 410501

Email Id - uday@excelplants.com

CallUs - +91-9225776611

OUR PRODUCTS - Industrial Mixers & Conveyors

Mixing processes and mixer designs depends upon the nature of the materials to be mixed. We have developed a wide range of mixing technologies to meet customer requirements in the needs of powder, paste, slurry and liquid applications.

⇓ Ribbon Blender

Ribbon Blender features single or twin counter

rotating shaft equipped with specially designed

paddles or ribbons. The twin shafts rotate

outward or inward if required, transporting

material along the shell towards the discharge.

Our Blenders are constructed out of SS 304

and equipped with the variable speed drive.

The mixer’s rugged industrial design coupled

with the described features makes this device

ideal for wet as well as dry granulation process

and provides years of trouble-free operation.

Ribbon Blender features single or twin counter

rotating shaft equipped with specially designed

paddles or ribbons. The twin shafts rotate

outward or inward if required, transporting

material along the shell towards the discharge.

Our Blenders are constructed out of SS 304

and equipped with the variable speed drive.

The mixer’s rugged industrial design coupled

with the described features makes this device

ideal for wet as well as dry granulation process

and provides years of trouble-free operation.

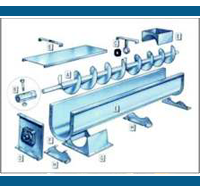

⇓ Screw Conveyors

We manufacture efficient Screw Conveyors which are equipped with digger teeth for positive

material flow, an oversized barrel for minimum deflection over a time period and are

exceptionally worn resistant. Being precision engineered our range of screw conveyors are used

for conveying sand crescent or any other material in granular, powder, cake form, in mild steel

and stainless steel. There is practically no rubbing action while operations of the machines so

these screw conveyors are easy to maintain.

We manufacture efficient Screw Conveyors which are equipped with digger teeth for positive

material flow, an oversized barrel for minimum deflection over a time period and are

exceptionally worn resistant. Being precision engineered our range of screw conveyors are used

for conveying sand crescent or any other material in granular, powder, cake form, in mild steel

and stainless steel. There is practically no rubbing action while operations of the machines so

these screw conveyors are easy to maintain.

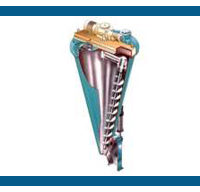

⇓ Nauta Mixer

Vertical Screw Blenders are excellent design alternatives

for product applications that are shear sensitive,

voluminous and also where space on the plant floor is at

a minimum.

Nauta mixers are widely used for mixing dry materials,

paste, cream and lotions. The principle of blending is

based on the differential travel speeds of product

particles in the conical section of the vessel. The material

from the bottom section of vessel is lifted by the screw

and spread over the upper sections.

Vertical Screw Blenders are excellent design alternatives

for product applications that are shear sensitive,

voluminous and also where space on the plant floor is at

a minimum.

Nauta mixers are widely used for mixing dry materials,

paste, cream and lotions. The principle of blending is

based on the differential travel speeds of product

particles in the conical section of the vessel. The material

from the bottom section of vessel is lifted by the screw

and spread over the upper sections.

⇓ Double Cone Blenders

The Double Cone Blender is efficient and versatile equipment for homogeneous mixing of dry powder and granules. This blender achieves absolute homogeneity in the blending of a wide variety of free-flowing, dry materials. This is accomplished even with dry materials, which are dissimilar in particle size and shape, because the double cone design interfolds the material regardless of its flow properties.

⇓ Paddle Mixer

Double Paddle Mixer are twin shaft with adjustable pitch of the paddle which enables variation of capacities and degree of mixing. These are ideal for mixing lumpy materials like filter cakes and materials with high moisture with dry material to make the mixture free flowing. The paddle mixer is used for the rapid mixing of wet cake or semi solids material. High rate mixing can be achieved this kind of mixer. Very sticky or semi solids can be easily handled in this mixer.

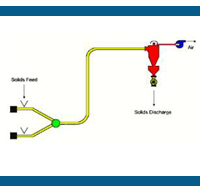

⇓ Pneumatic Conveying Systems

EXCEL PLANTS VACUUM CONVEYING SYSTEMS works on negative pressure for conveying the material from one or number of pickup points to one discharge point. This system is best suitable for providing dust free conditions around inlet. The system is composed of pick-up nozzle, divertor valve, discharge lock, exhauster & piping.